Traveling Sherline Show

Soft Jaws

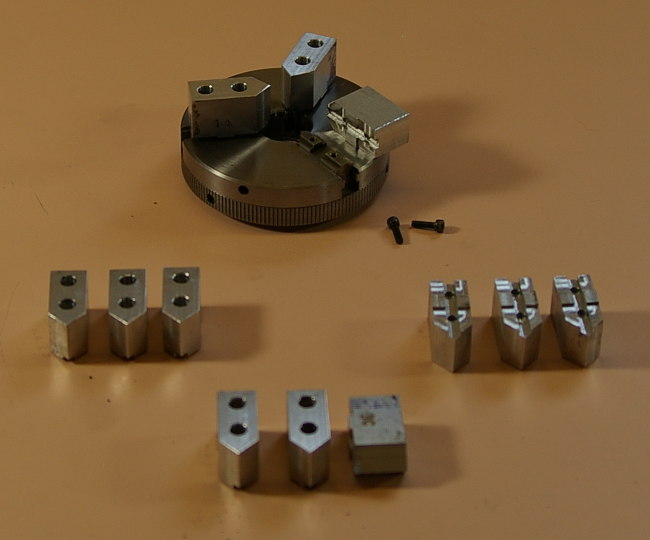

Sherline makes a two piece jaw for its chucks. I've had good luck with soft jaws on my large lathe so wanted to try them on the Sherline. I ordered a set of master jaws and one set of steel top jaws. They make a number of top jaws in steel, aluminium, nylon, brass, etc. The top jaws cost between $54 (steel) and $78 (teflon). They are very proud of their jaws. I thought I could make some given one set of top jaws to measure from.

I cut up some surplus 1/2" aluminium plate using a slitting saw. Squared them up and cut two lengths of about 5". Using a 2" toolmaker's vice tilted at 45 deg in the 6" vice I cut 90 deg included angle on each length. Each 5" length was cut into 6 pieces and squared to 0.7". All this was done on the knee mill. Could be done on the Sherline but would take a lot longer.

Then on the CNC Sherline mill I cut the bottom to fit the master jaw. This took me some trial and error. I wanted a very good fit so the jaws could be removed/replaces and retain their position. After figuring out the G-code and tooling I cut the base of four sets of aluminium jaws.

Finally, drilled holes with counter sink for 4-40 socket headed cap screws.

|

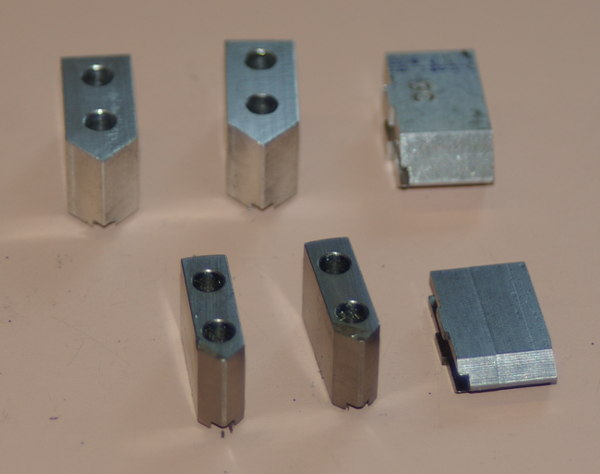

These are cut on the lathe to be dead square for general use or for a particular job. A spacer is put in the chuck to hold the jaws tight to the scroll for either holding on the exterior of a part or on the interior. Technically the size cut should be the size of the part to be held. That is their purpose. I've found they are "good" for a range of sizes and I use them instead of the stock hardened jaws, at least on my large lathe. They don't mar parts as bad. We'll see if they are as useful at the Sherline size.

Here is a picture of the new aluminium jaws along with the Sherline steel jaws.

|

The stock jaws in the front and new aluminum jaws in the back.